Fuel Rim Torque Specs . The fine threads used for the rotor assembly nuts should be torqued to 34ft. To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels. choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation. apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel.

from repairfixajumbes7f.z4.web.core.windows.net

apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. The fine threads used for the rotor assembly nuts should be torqued to 34ft. 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels. To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts. choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation.

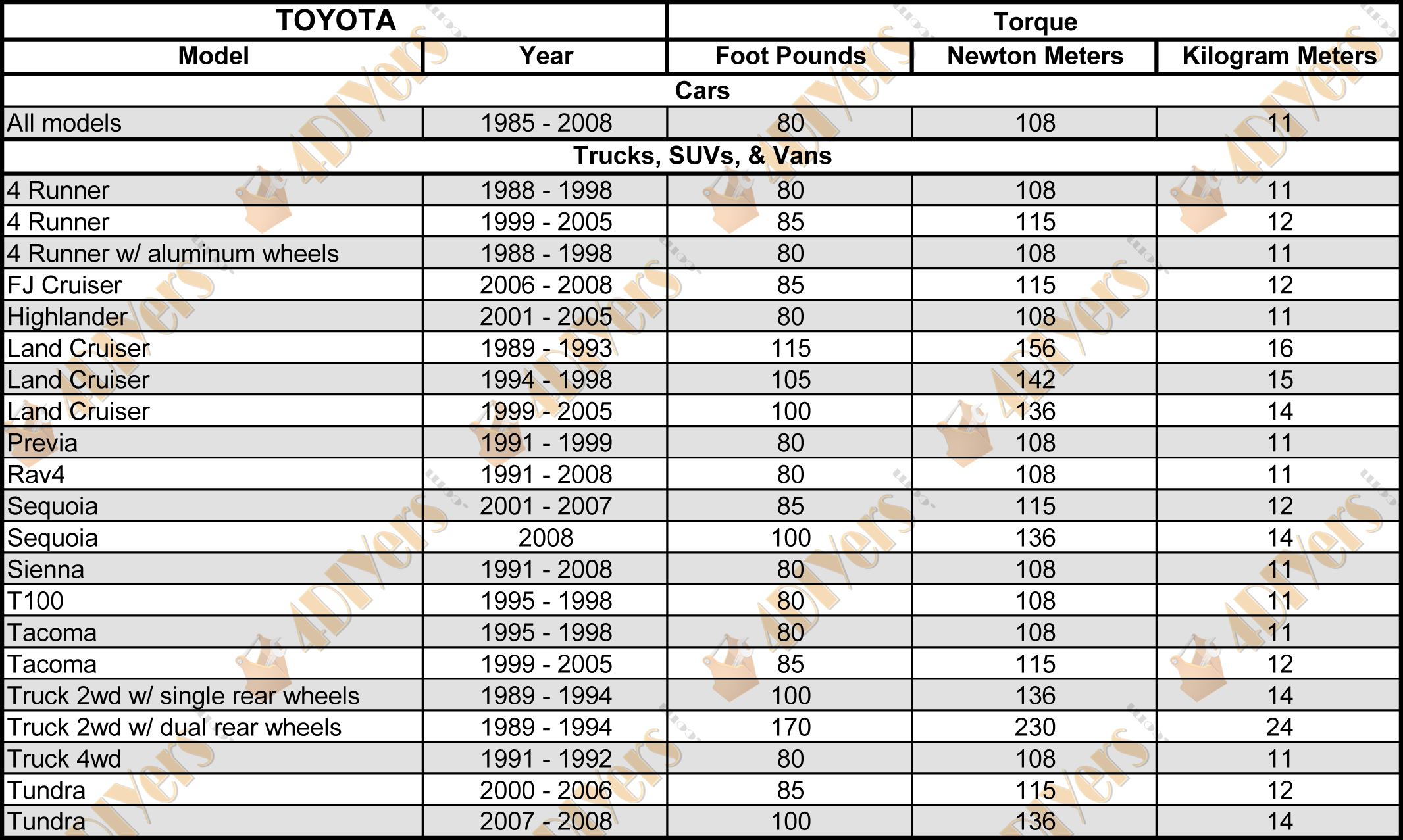

Automotive Torque Specifications For Lug Nuts

Fuel Rim Torque Specs The fine threads used for the rotor assembly nuts should be torqued to 34ft. apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. The fine threads used for the rotor assembly nuts should be torqued to 34ft. choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation. To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts.

From automotiveimportmarket.com

Fuel 1Piece Wheels Torque D689 Wheels & Torque D689 Rims On Sale Fuel Rim Torque Specs using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. The fine threads used for the rotor assembly nuts should be torqued to 34ft. apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. choosing. Fuel Rim Torque Specs.

From tiresupplynetwork.com

The New 2022 Lug Nut Torque Chart is Now Available at Tire Supply Network! Fuel Rim Torque Specs 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. apply blue or red loctite on the coarse thread end of each stud and install to finger tight. Fuel Rim Torque Specs.

From dsau.com.au

Torques settings for Kubota V2203 Diesel Spares Fuel Rim Torque Specs using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation. The fine threads used for the rotor assembly nuts should be torqued to 34ft. apply. Fuel Rim Torque Specs.

From mungfali.com

Wheel Torque Specs Chart Fuel Rim Torque Specs choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation. To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts. 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels.. Fuel Rim Torque Specs.

From www.performanceplustire.com

Fuel Wheels Torque D690 Matte Bronze Rim Performance Plus Tire Fuel Rim Torque Specs The fine threads used for the rotor assembly nuts should be torqued to 34ft. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. To ensure. Fuel Rim Torque Specs.

From repairfixajumbes7f.z4.web.core.windows.net

Automotive Torque Specifications For Lug Nuts Fuel Rim Torque Specs To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts. choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation. 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels.. Fuel Rim Torque Specs.

From mechanicanticipeg3m.z13.web.core.windows.net

Lug Nut Torque Specifications Fuel Rim Torque Specs 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels. The fine threads used for the rotor assembly nuts should be torqued to 34ft. apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. To ensure proper installation procedures, follow the. Fuel Rim Torque Specs.

From www.justanswer.com

Isuzu Engine Torque Settings 4HF1, 4JJ1, 4JK1, 4 Fuel Rim Torque Specs choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation. To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little. Fuel Rim Torque Specs.

From support.karavantrailers.com

What is the torque spec for my tires? Karavan Trailers Fuel Rim Torque Specs apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to. Fuel Rim Torque Specs.

From www.autozone.com

Repair Guides Torque Specifications Torque Specifications Fuel Rim Torque Specs 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels. The fine threads used for the rotor assembly nuts should be torqued to 34ft. To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts. using the manufacturer recommended torque also. Fuel Rim Torque Specs.

From www.scribd.com

Cummins CSeries Engine Torque Specifications Fuel Injection Fuel Rim Torque Specs using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts. apply blue or red loctite on the coarse thread end of each stud and install. Fuel Rim Torque Specs.

From www.2carpros.com

Torque Specs Just Trying to Get Torque Specs For Upper and Lower... Fuel Rim Torque Specs apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels. The fine threads used for the rotor assembly nuts should be torqued to 34ft. To ensure proper installation procedures, follow the. Fuel Rim Torque Specs.

From www.felling.com

Service Felling Trailers Wiring Diagrams, Wheel Toque Fuel Rim Torque Specs The fine threads used for the rotor assembly nuts should be torqued to 34ft. 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels. apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. using the manufacturer recommended torque also. Fuel Rim Torque Specs.

From www.rvcampgear.com

22.5 Wheel Torque Specs RV Camp Gear Fuel Rim Torque Specs using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. The fine threads used for the rotor assembly nuts should be torqued to 34ft. 20 headquartered in denver, colorado, wheel pros is a leading designer, marketer, and distributor of branded aftermarket wheels. To ensure proper installation procedures,. Fuel Rim Torque Specs.

From old.xs650.org.au

Torque Specs Fuel Rim Torque Specs apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little. Fuel Rim Torque Specs.

From www.speedwaymotors.com

AFCO 21207X Three Stage Torque Link Free Shipping Speedway Motors Fuel Rim Torque Specs apply blue or red loctite on the coarse thread end of each stud and install to finger tight into wheel. choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little. Fuel Rim Torque Specs.

From www.socalcustomwheels.com

Fuel 1Piece Wheels Torque D689 Wheels SoCal Custom Wheels Fuel Rim Torque Specs To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts. The fine threads used for the rotor assembly nuts should be torqued to 34ft. choosing the right size and type of lug nuts for your fuel wheels is essential for proper maintenance and installation. apply blue or. Fuel Rim Torque Specs.

From mungfali.com

Wheel Torque Specs Chart Fuel Rim Torque Specs To ensure proper installation procedures, follow the manufacturer’s torque specifications and use a torque wrench to properly tighten the lug nuts. using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the. The fine threads used for the rotor assembly nuts should be torqued to 34ft. apply. Fuel Rim Torque Specs.